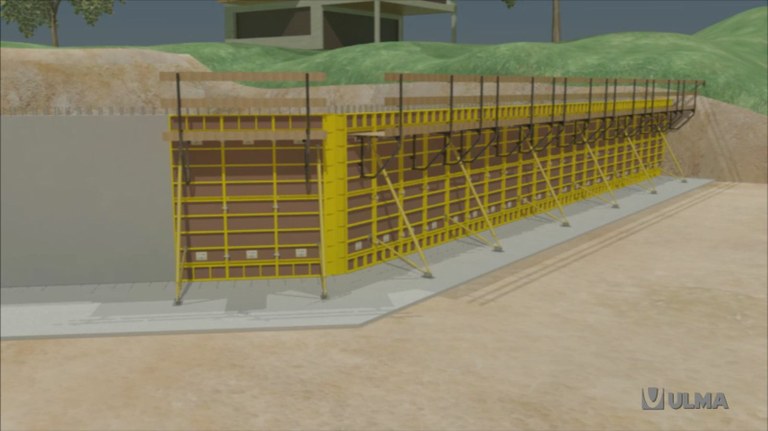

The LGW lightweight panel formwork is a versatile system for the solution of any vertical geometry in building construction. Manual handling or crane-assisted, it has a simple panel joining with clamps.

Remarkably strong and durable panel design with galvanised or painted frames and phenolic or composite board.

- Light panel formwork (30 kg/m²) for the solution of any wall, column and foundation geometry.

- High load capacity panels:

- Maximum constant pressure: 60 kN/m² (50 kN/m² for the 3 x 2.4 m panel)

- Maximum hydrostatic pressure for the 3 m panel range: 75 kN/m²

- Maximum deflections: line 6 according to DIN 18202

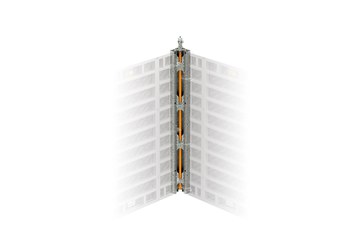

- Columns:

- Widths from 10 to 65 cm

- Maximum constant pressure: 80 kN/m²

- Wide panel range:

- Height: 3 m, 2.4 m, 1.2 m, 0.6 m.

- Width: 0.9 m, 0.75 m, 0.6 m, 0.45 m, 0.3 m.

- Big size panel: 3 x 2.4 m

- The shuttering face comprises a 15 mm phenolic birch plywood, providing an excellent concrete finish.

- Simply lighter:

- Up to 10% lighter than similar systems.

- It can be manually assembled reducing crane use on-site.

- Gang forming available for fast forming.

- Designed to last:

- High durability, hot-dip galvanised or painted panels.

- Reinforced steel frame on the corners protected against the damage of impact.

- Faster setting and forming:

- Panel sizes specifically designed to reduce joints between them and minimise infill areas.

- Less number of ties for a faster assembly.

- Easy and fast panel connection using easy-to-use clamps, easily fastened with a single hammer blow.

- Multifunctional panel range:

- A wide range of panels up to 3m high, perfect for complex geometrical structures.

- Higher load capacity and performance compared to other light panel formwork systems.

- The lateral holes in the panel profile are designed for bulkhead, corner and column solutions with universal panel.