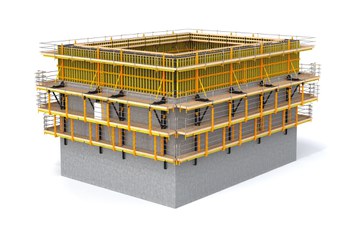

The new generation BATEK modular formwork is perfect for the construction of all kinds of vertical concrete structures, aimed at both the building construction and civil engineering sectors (walls, columns, abutments, footings, etc.).

It’s distinctive for high-performance-assembly rates with a great reduction in labour and runtime, thanks to the one sided tying option.

The system is comprised mainly of panels which, joined with clamps is compatible with other ULMA vertical formwork. It solves all types of geometries effectively and safely, always providing excellent concrete finishes.

- Designed to withstand high concrete pressures.

- Permissible concrete pressure:

- Standard Panel: 80 kN/m²

- Universal Panel: 100 kN/m²

- Maximum deflection:

- Standard Panel: 60 kN/m² (line 7, table 3 DIN 18202).

- Standard Panel: 80 kN/m² (line 6, table 3 DIN 18202).

- Universal Panel: 100 kN/m² (line 7, table 3 DIN 18202).

- Wide range of panels:

- Height: 3.3 m, 2.7 m, 1.2 m, 0.6 m.

- Width: 2.4 m, 1.2 m, 0.9 m, 0.75 m, 0.6 m, 0.45 m, 0.3 m.

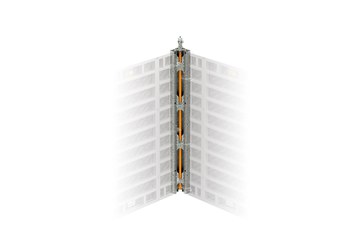

- All the panels provide 3 tying options.

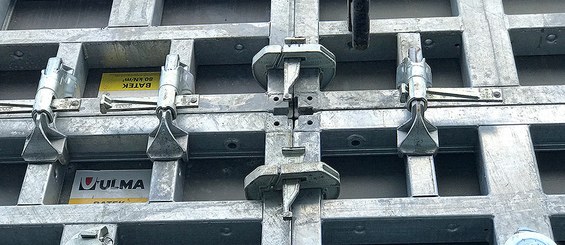

- Solution 1: One sided tying with the BATEK tie.

- Solution 2: One sided tying with standard market DW15 or DW20 tie rods.

- Solution 3: Two sided traditional tying.

- The patented BATEK nut fits all three ties, the BATEK tie, DW15 and DW20, there are therefore less component references.

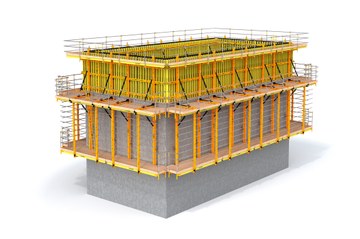

- High productivity and more labour savings:

- Reduction of up to 50% in formwork and stripping times, thanks to the one-sided tying system.

- Up to 40% less tying points compared to traditional panel formwork systems.

- Standard and Universal Panels, symmetrical on the X-Y axes, preventing possible assembly errors.

- Easier tying process:

- Innovative quick assembly of the BATEK nut with no tools needed.

- Fast and accurate wall thickness adjustment thanks to the BATEK tie. Easy and precise 3-step operation with no tools required (Unlock, Set length, Lock).

- BATEK tie assembly with no need of spacer tubes or cones, just one tool is needed - a 24 mm hex wrench.

- Low maintenance and long lifespan:

- No sealing components or threaded elements on the panels, which significantly reduces panel checking and repair stops and associated costs.

- Easy and quick inspection and replacement of sealing components located on the tying system, without any tools needed.

- High durability, hot-dip galvanised panels with reinforced steel frame on the corners.