Description

Best known as Mane Garrincha, it is one of the main venues of the 2014 Football World Cup. After the demolition of the old stadium, this new sports complex accommodates more than 71,000 spectators in an area of 188,000 m2.

This project faces several challenges: nearly 5,000 tons of auxiliary products, in a construction process with less labour and shorter lead times, always maintaining a high level of safety.

ULMA Solution

The peculiarity of this stadium resides in the 288 columns of 46 m height across the entire complex, on which the compression ring rests. For the construction of the circular columns of 1.20 to 1.50 m diameter, CLR formwork has been used in successive tiers of 4 m. The BRIO system used as working platforms, ensured workers' safety at great height.

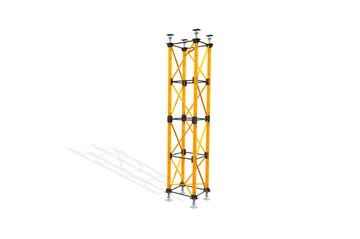

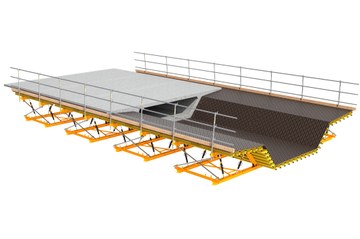

The construction of the compression ring (22 m width and 46 m height) meant a great technical challenge. This is where ULMA as a cutting-edge company for formwork technology comes in value. MK Structures, resting on climbing brackets anchored to the 288 columns, supported the compression ring, which avoided the use of a large volume of conventional shoring and resulted in considerable time and cost savings. For the construction of the grandstand beams (12 m height), MK Structures on BRIO Shoring were used.

The foundations were large repetitive blocks. The versatility of the COMAIN formwork suited this job.

As shoring system for slabs and beams, ALUPROPs have provided lightness and adaptability to the different slab heights. The Trolley VR has facilitated the transfer of BRIO and ALUPROP towers to each new pouring stage thus avoiding their dismantling. Thereby the efficiency of the project could be increased, and the material input reduced.

The production manager of the builder consortium, Marcos Aparecido Conchis, states that the expectations set on ULMA have been exceeded, with a high quality service, continuous advice and strict compliance with supply commitments.